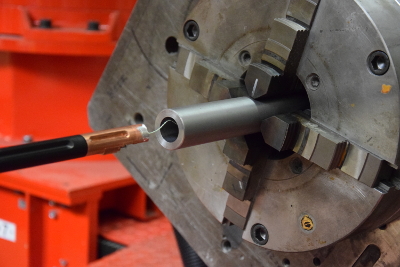

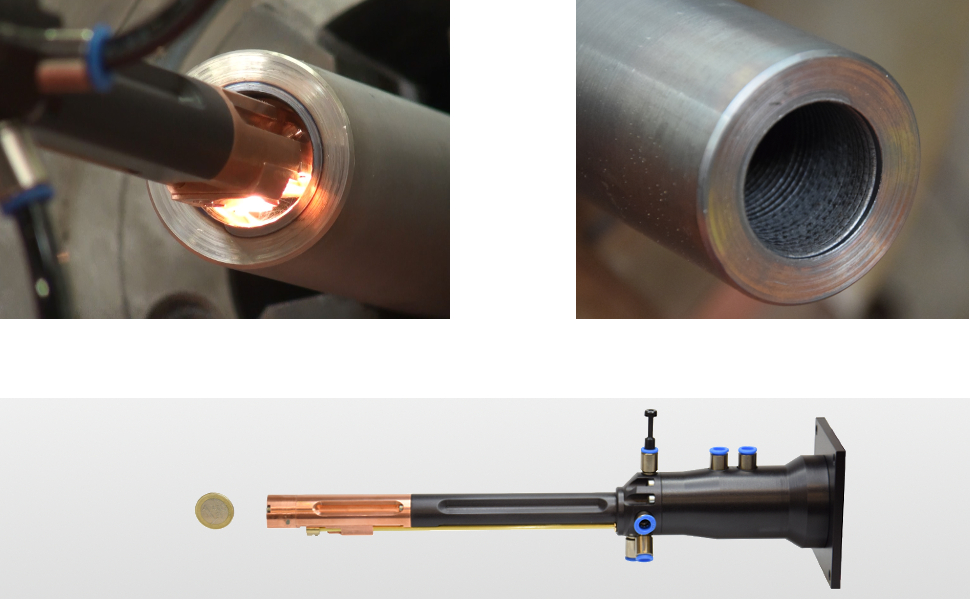

For the first time our laser system technology has succeeded in developing a processing optic for laser cladding and laser hardening in an inner diameter of only 25 mm. The optic is used by the end customer to the inner coating of jacks and molds. The maximum immersion depth is 150 mm for this specific case. During acceptance test monolayers of about 1 mm were welded onto the pipe surface. An increase in the depth of immersion to 300-500mm is conceivable. For larger inside diameters this concept can be used for immersion depths of up to 1.5m, from both sides 3m.

The optical components and the beam path are designed for a power of 1 kW. Developed by NUTECH cooling allows stable coating processes of 30 minutes and the temperature of the optical components during which continuously at 60 ° C at pipe temperatures of over 200 °.

Applications include the welding of internal bores, passages, bushings, bearings, running surfaces, bearing seats, Connecting rod up to 25 mm by a cohesive welding process.