Laser hardening

Laser hardening – an innovative metal treatment technology with the laser that refines metallic surfaces with precision and efficiency for maximum hardness and durability.

Laser hardening – an innovative metal treatment technology with the laser that refines metallic surfaces with precision and efficiency for maximum hardness and durability.

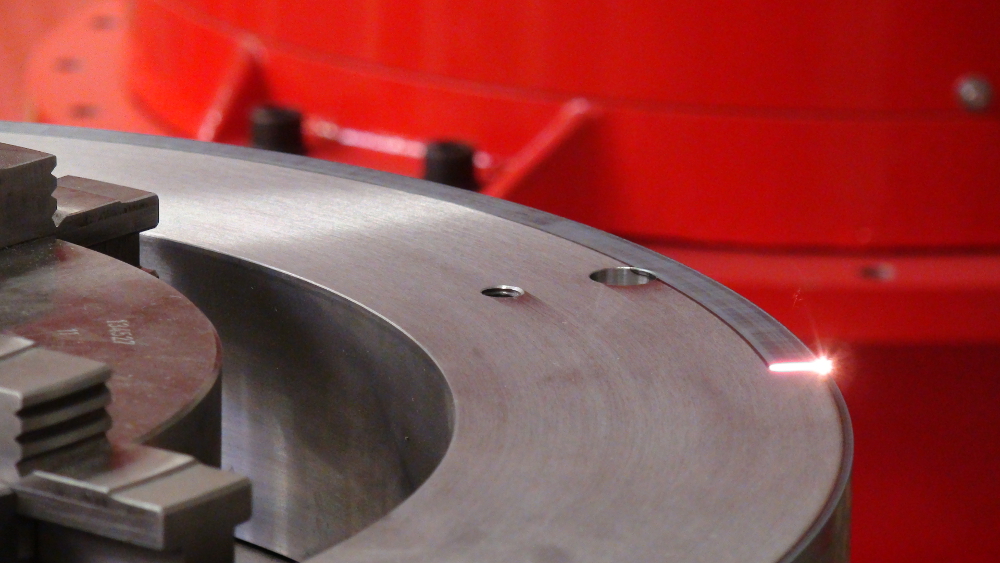

Laser hardening is a process of laser surface technology aimed at specifically improving the wear behavior of metal components.

In laser hardening, also known as case hardening, the energy of the laser beam is applied directly to the surface of the component. The surface layer is heated to hardening temperature (>1000°C) in a very short time, locally and precisely.

An advantage of using lasers for surface treatment is that the heat input is relatively low, allowing for rapid heat dissipation into the base material of the workpiece. This leads to self-quenching, combined with the formation of a martensitic microstructure and the “freezing” of the hardened structure.

Due to the high heating rate in laser hardening, a very tough, fine-grained microstructure is created. The self-quenching effect results in a very low risk of crack formation. Because of the highly precise energy input, the component undergoes relatively minimal thermal influence in the case hardening process using laser light. Consequently, the minimal hardness distortion in this surface technology is a significant advantage.

Basically, all steels with a sufficient carbon content (> 0.2%) are hardenable if they undergo a phase transformation. The achievable hardness is determined by the carbon content.

Important laser-hardenable steels can be classified into the following groups:

Transformation-free steels, such as non-magnetic Cr/Ni steels

or ferritic steels with high Cr content, cannot be hardened either with laser beams or other methods.

Cast iron and black tempered cast iron are also hardenable. The same conditions apply as for hardening steel. However, it should be noted that the carbon in the graphite is not involved in the hardening process. The decisive factor is the carbon content present in the base structure. The form of graphite does not affect hardenability. The types of cast iron that can be hardened include those with lamellar graphite, spheroidal graphite, temper carbon, and vermicular graphite.

Pure iron cannot be hardened through a phase transformation. The required element for this is carbon.

We also have many years of expertise and technology in this area. For laser hardening of internal surfaces, for example, our Laser System Technology division manufactures and uses special optics. Please feel free to contact us if you have questions about contract manufacturing.

For any questions about our range of services, laser technology, or our offers, you can contact us here. We are happy to advise you on your industry-specific needs and develop a suitable solution together with you.

Request NowServices and contract manufacturing with state-of-the-art laser technology: laser welding, laser cutting, and laser surface treatment. Various materials and assemblies up to large-scale production.

Specialized department for the development and manufacturing of processing optics for high-power lasers, particularly focused on small designs for intricate application areas.