High service quality is our product, based on technical expertise and an extensive range of high-grade laboratory equipment. We also want to provide you with an insight into our laboratory equipment to show you the different options that our Analysis and Testing Centre offers.

We work with the following instruments for materials analysis

- SPECTOMAXX optical emission spectrometer

Stationary, to identify the elemental composition of Fe, Ti, Cu and Al alloys - 2 energy-dispersive X-ray analysis systems (EDX) EDAX Genesis and EDAX TEAM with SDD detectors for elemental analysis and elemental distribution mapping

- 2 coarse/fine granulators to shred films and refuse-derived fuel

- Helium leak tester to determine leak tightness in components

- PARR calorimeter to determine heat and calorific value

- ELTRA carbon analyzer, measurement range: 0.005-100% carbon

- SG4000ex personal air samplers, 0.05-3.5l/min.

- MACHEREY-NAGEL photometer

- DIENER ELECTRONIC plasma etcher

- 2 scanning electron microscope (SEM) by ZEISS, EVO MA10 and MA25, accelerating voltage 0.2-30 kV, chamber pressure 10-400Pa, SE and BSD detectors; 5-axis table control for samples up to 0.5kg; samples up to 5 kg in x,y- direction; max. sample dimensions: 130x130x210 mm

- SG12 and GSA 50-1 air samplers, 3.0-50l/min.

- FRITSCH sieve machine for determining particle size distribution

- BAL-TEC sputtering system (Au/Ag evaporation)

We have the following machines and appliances in materials testing

for use on a daily basis

- Diamond disc to sharpen diamond saw blades

- 2 BÜHLER mounting presses to produce metallographic specimens, 30, 40, 50 mm in diameter

- Ball crater device

- 2 WOLPERT low load hardness testers, measurement range 0.05-1 HV

- Environmental chamber for corrosion test with NaCl solution

- 2 ZEISS/ REICHERT+JUNG optical microscopes, with motor. x, y, z axis sample table to some extent, reflected light, 8-1250x magnification, differential interference contrast (PIC), polarisation contrast (Pol), bright field (B), dark field (D)

- Pendulum impact testing machine: 150J and 300J, room temperature, -20°C, -40°C and -197°C, WOLPERT

- 3 grinding/ polishing machines to prepare metallographic samples, ATM/BÜHLER

- 4 cut-off machines to wet-cut workpieces, max. sample size 240/550/550mm (H/W/D)

- WOLPERT universal hardness tester for HRC, HRB, HRH, HV, HBW

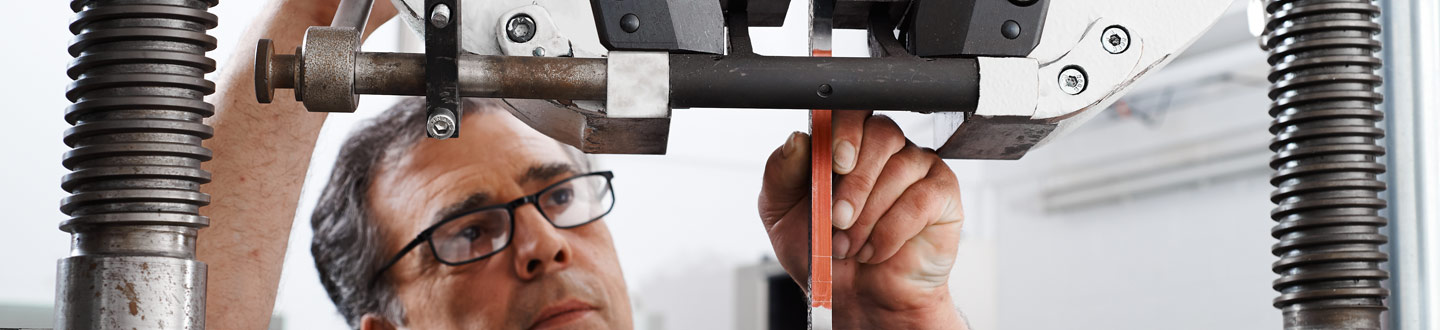

- 2 universal test machines 100 kN and 200 kN, for tensile, compressive and bending tests, WOLPERT/SCHENCK-TREBEL/ DOLI